A Revolutionary Approach

Structural Health Monitoring redefined

An innovative cloud platform for the assessment of structural health using true simulation-based Digital Twins and Artificial Intelligence

Leveraging the Cloud to Protect the Built World

WeStatiX SHM represents a new way to manage Structural Health Monitoring. It introduces true simulation-based Digital Twins connected to their real counterparts with IoT sensors, and turns their data into actionable information thanks to advanced AI algorithms. At any point in time, the Digital Twin behaves like the monitored object, and allows for virtual inspections directly in the browser. Without spending countless hours on complex calculations, Engineers can now gain insight on the structural behavior and perform predictive maintenance with ease.

The Company

We develop a revolutionary technology for predictive maintenance

Meet the Team

We are an award-winning multidisciplinary team based in Bolzano, Italy, with a passion for engineering and great expertise in software development. We work with businesses and people to create a safer world.

“Many people talk about the digitalisation of infrastructures as a slow process to be undertaken in an unspecified future. With WeStatiX SHM this is already possible: the structure status is continuously analyzed, the predictive analysis through AI is very reliable and the data from the digital twin are made available in real time.”

Davide BigoniProf. UniTN

Our work flow

Object

The first step is to identify the structure to be monitored. WeStatiX SHM is able to assess the health of any kind of structure, ranging from bridges and viaducts to tunnels, from buildings to wind turbines, from rockwalls to embankments and slopes, and many more. While it is good to have as much information as possible of the monitored object, it is not always possible to have access to material parameters, maintenance history, etc., especially for older artifacts: not to worry, since WeStatiX SHM can correctly identify most missing information while it learns from the structural behavior. Did you know? It is also a great tool for structures under constructions, enabling managers to adapt the design to the conditions on site.

01

Sensors connection

WeStatiX SHM does not require a specific type of sensor to work. Instead, it can flexibly adapt to the type of measurements that best fit the current use-case, even if they are already existing on the monitored object. Thanks to its capabilities of global structural analysis, WeStatiX SHM can correctly identify behavior even with small amounts of data and limited number of sensors, which directly translates into great cost savings. Thanks to its intuitive user interface, it is easy to connect the telemetry streams with the cloud, and start the monitoring process.

02

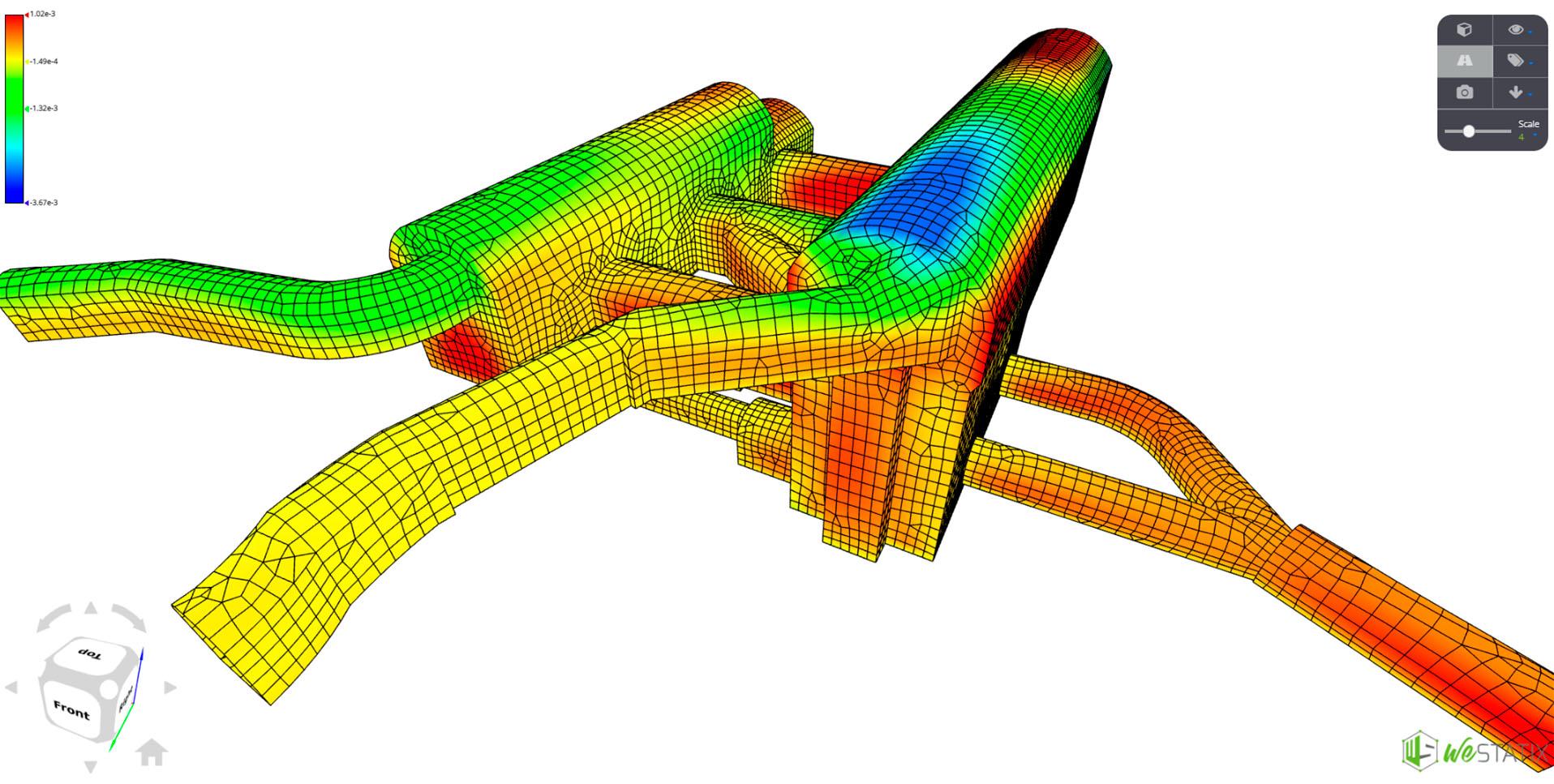

Digital Twin

The digital counterpart of the monitored object is represented by an advanced Digital Twin that looks, behaves and responds exactly like the real structure. Our revolutionary Twin Builder module makes it extremely easy to build the Digital Twin. Oftentimes, a 3D model is already available as FEM or BIM, or it can be generated with our Twin Designer module, or with your favorite software suite: WeStatiX SHM is compatible with a large number of third-party formats, which can be imported directly, and then extended with additional information from the comfortable UI.

03

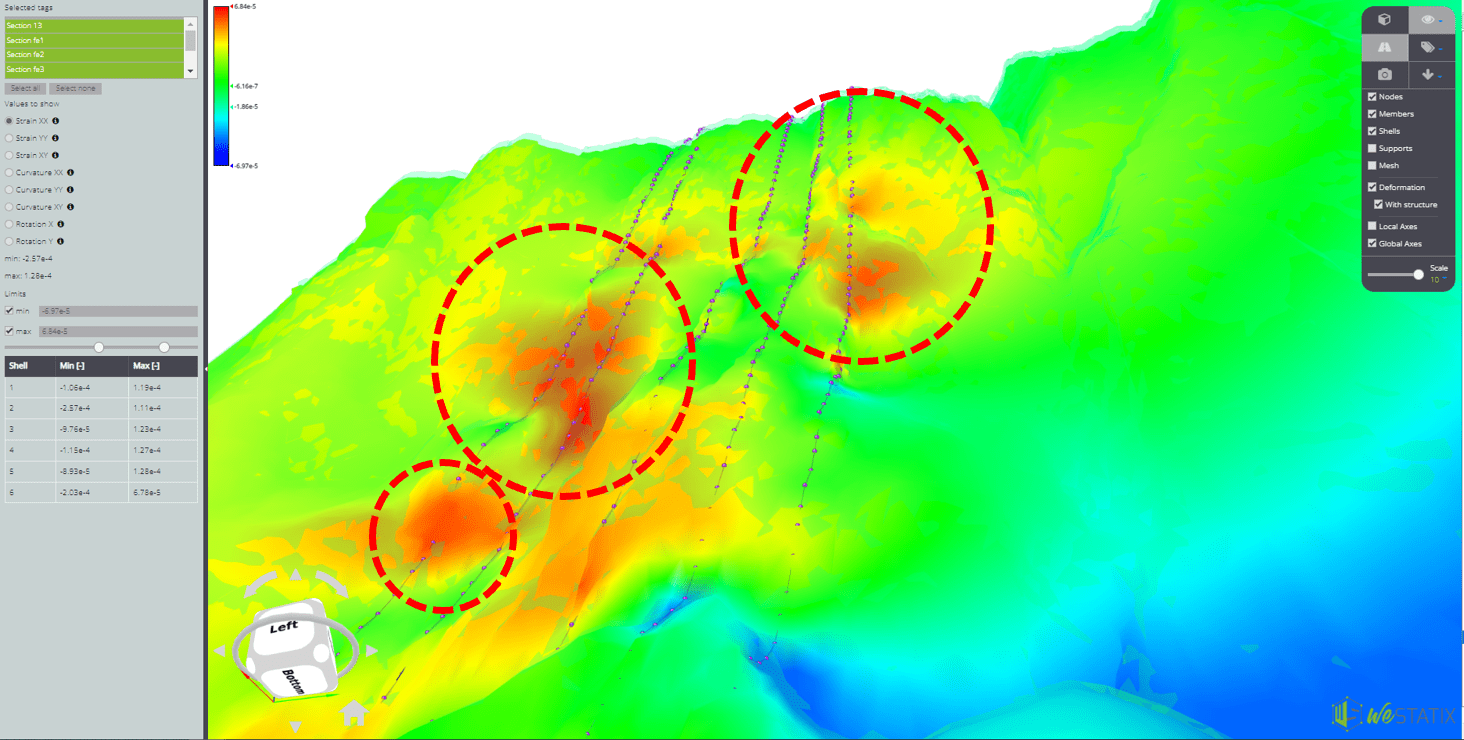

Automatic calibration

WeStatiX SHM enables the user to make the Digital Twin live by connecting it with telemetry data and performing continuous FEM simulations in the cloud. The advanced algorithms within WeStatiX SHM allow calibration of the Digital Twin based on inverse analysis, so that unknown parameters can be identified by observing the behavior of the real structure, and behavior of the Twin can be adjusted until it perfectly matches the real world.

04

Monitoring and Artificial Intelligence

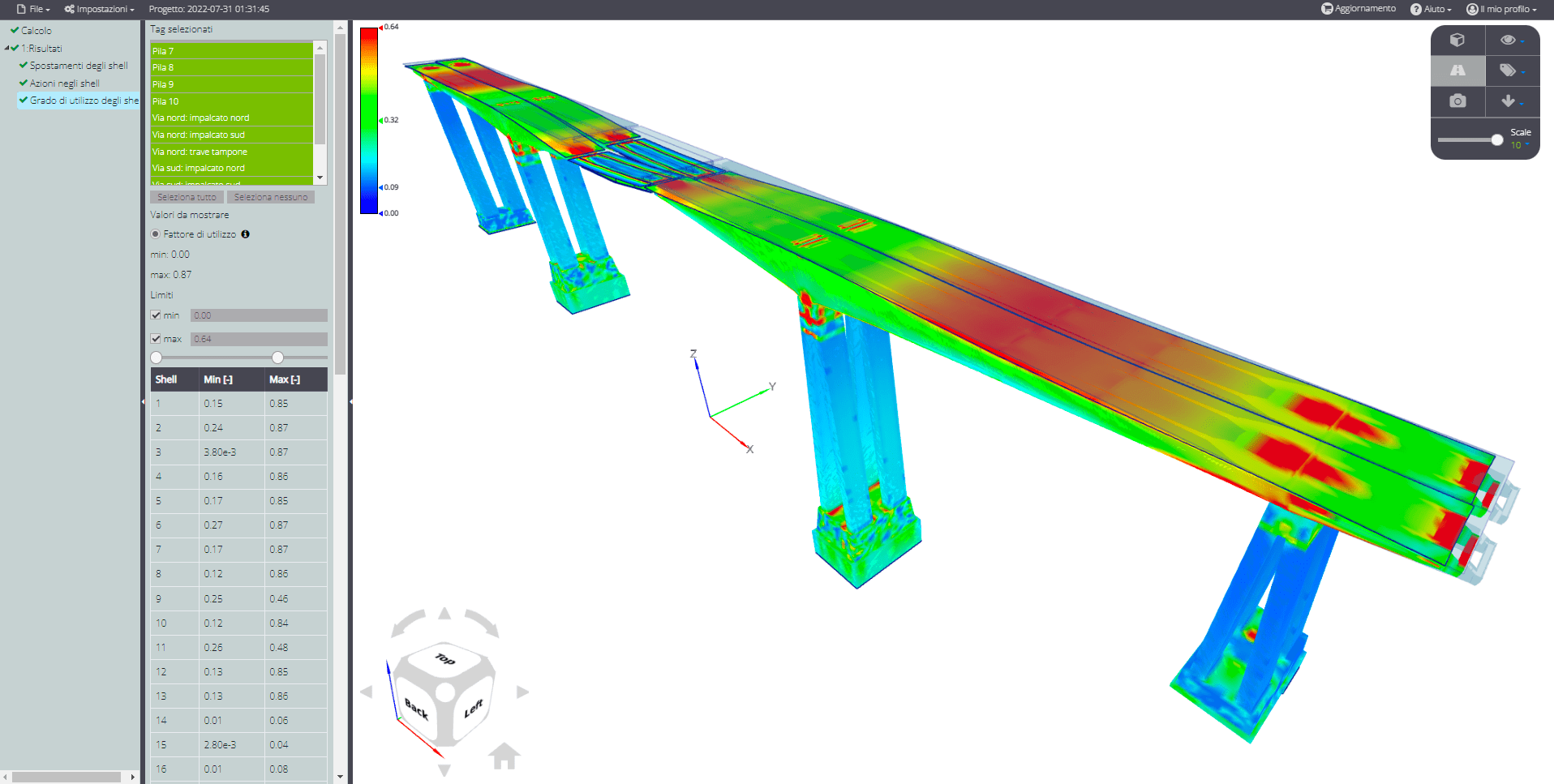

The powerful monitoring and post-processing module of WeStatiX SHM makes real-time monitoring finally practicable. Results of the current simulation are easily accessible through the interactive 3D interface, which enables virtual inspections any time, from any device. A comprehensive, easy-to-use dashboard exposes all data and reports for analysis. Finally, the physics-informed Artificial Intelligence system continuously inspects the state of the Digital Twin, predicts its future behavior and warns about the necessity for interventions.

05

Our Revolutionary Approach

A unique cloud-based platform that is able to interpret the physical behaviour of a structure based on data provided by installed sensors, and predict its future behaviour through the use of artificial intelligence.

Real-Time Monitoring

WeStatiX SHM can continuously collect data from sensors embedded in the physical asset, and synchronize the behavior of the Digital Twin. This real-time monitoring enables early detection of anomalies, potential issues, or changes in the system's behavior.

Predictive Maintenance

By analyzing the data from the Digital Twin, patterns and trends can be identified, allowing for predictive maintenance. Our AI assistants suggest maintenance actions that can be scheduled before a failure occurs, reducing downtime and increasing the lifespan of the asset.

Performance Optimization

With the ability to simulate different scenarios, Digital Twins can be used to optimize the performance of the physical asset. By tweaking parameters in the virtual model, operators can identify the most efficient settings in the real-world system.

Risk Assessment

Digital Twins can be used to conduct risk assessments by simulating critical events or worst-case scenarios. This allows organizations to proactively plan for potential risks and take preventive measures.

Data-Driven Decision Making

WeStatiX SHM provides a wealth of data and insights, which can be used for data-driven decision-making. It empowers operators to make informed choices based on real-world data and simulations.

Virtual Inspections

The 3D interface of WeStatiX SHM presents the state of the Digital Twin directly on screen, and allows for interactive virtual inspections. Each point of the structure can be examined with ease, while a powerful dashboard gives a complete overview of the simulation results.

Key Features

WeStatiX SHM (Structural Health Monitoring) is a novel solution that enables the virtual 3D inspection of existing structures through the web browser, automatic FE simulation, and predictive analysis of the future behaviour of the monitored structure.

show me the features